Our Products

- VARIABLE LOAD EFFORT SPRING SUPPORTS

- CONSTANT LOAD EFFORT SPRING SUPPORT

- RIGID ROD HANGER SUPPORTS

- PIPE SUPPORTS SLIDING & GUIDING TYPE

- HELICAL & COMPRESSION SPRING

- PIPE CLAMP, BEAM BRACKET, BASE CLAMP

- SLIDING SUPPORT (PTFE & GRAPHITE)

ISO 9001 : 2025 Cerified Company

Mfg. of Spring Hanger Support and

Allied Equipments Heavy Fabrication

Kristal’s spring supports ensure reliable load compensation and thermal movement handling in piping and structural systems

Pipe line under operation is being supported by various ways. Equipment like rigid Supports or Hanger Supports are adopted at line pipe as and anywhere these are suit. Rigid Support does not allow the movement of pipe line at supporting point at any direction.

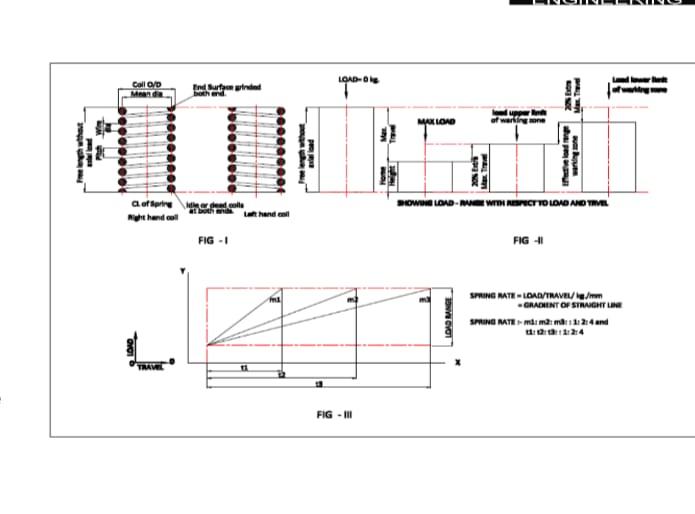

While Hanger Supports like Variable Hanger Supports or Constant Effort Hanger Supports are allowing vertical movement to some extent as specified by designer. Due to vertical movement in either direction, up or down, stress may develop in line pipe depending on the magnitude of movement traversed.

Within elastic limit and according to specified limit of movement, permanent set up of strain cannot develop in the line pipe and thus line pipe is not injured due to deflection under load in the pipe. The vertical movements are controlled by hanger support.

When a variable hanger support is directly subjected to the pipe under load with movement, it allows the movements and the magnitude of movement will be increased or decreased according the increased or decreased loads developed in line pipe.

This variable magnitude of load with movements is controlled by variable hanger supports. Sometimes a lengthy movement occurs due to which an adequate high stress develops and the corresponding strain would be the cause of injury of the line pipe.

In this case, to minimize the strain an additional continuous effort is required against the load developed in pipe due to which the lengthy movement takes place in either direction up or down.

A Constant Effort Hanger Support is adopted which exerts a constant effort against the load developed in pipe irrespective of magnitude of movement within a limitation as specified by the designer.

To control quality at every stage, materials are checked or inspected for physical dimensions starting from procurement.

Variable spring supports are used where pipelines are under high pressure, high temperature and result in vertical movement. To allow vertical movement, all the loads are taken care of by variable spring support in both the hot and cold position. These are used to protect valuable instruments, pipelines and critical components.

Constant spring supports ensure constant load during movement of pipelines due to thermal expansion. They are ideal for accommodating large vertical displacements while maintaining constant force. The bell-crank lever balances load and movement to reduce kinetic variation.

Designed to suspend from above, these constant spring hangers support piping that moves vertically. They use a pivot-based mechanism that keeps load constant during movement, protecting pipe joints from stress.

Adjustable spring supports allow fine-tuning of spring tension on site. Useful where load conditions vary or alignment needs adjusting during commissioning. Equipped with tension locking and preset indicators.

Helical spring supports offer simple elastic support for lighter loads and flexible connections. They absorb small vertical displacements and vibration. Ideal for static equipment connections, tanks, or vessels.

Trusted experts in spring hangers and pipe support systems for over 20+ years

Important Links

Customer Spotlight

Customer Service

FAQ

Company

About Us

Products

Team Members

Services

Contact

kristalengineering777@gmail.com kristalengineeringke3@gmail.com

+91 70445 15797 +91 73590 06572

Balitikuri, Bamunpara, Howrah - 711113, West Bengal, India